|

To

purchase vacuum suction tool stand click here

Vacuum

suction tool stand VSTS-WZ

We have developed under the patent

license of Mitutoyo

Co., Ltd. worldwide precision measuring equipment manufacturer.

Utilizing Mitutoyo patent [No. 4616563]

This is the next-generation tool stand to replace

the conventional magnet stand (magnet base).

It is used when measuring with a dial gauge or pick

gauge (pick tester).

Vacuum

suction tool stand document

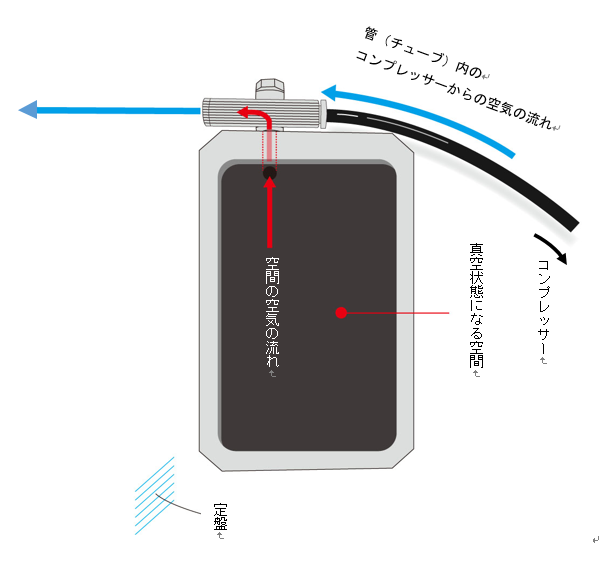

<Adsorption principle>

Adsorption principle explanation diagram of vacuum

suction tool stand

The figure below shows the bottom of vacuum suction

tool stand.)

<Use>

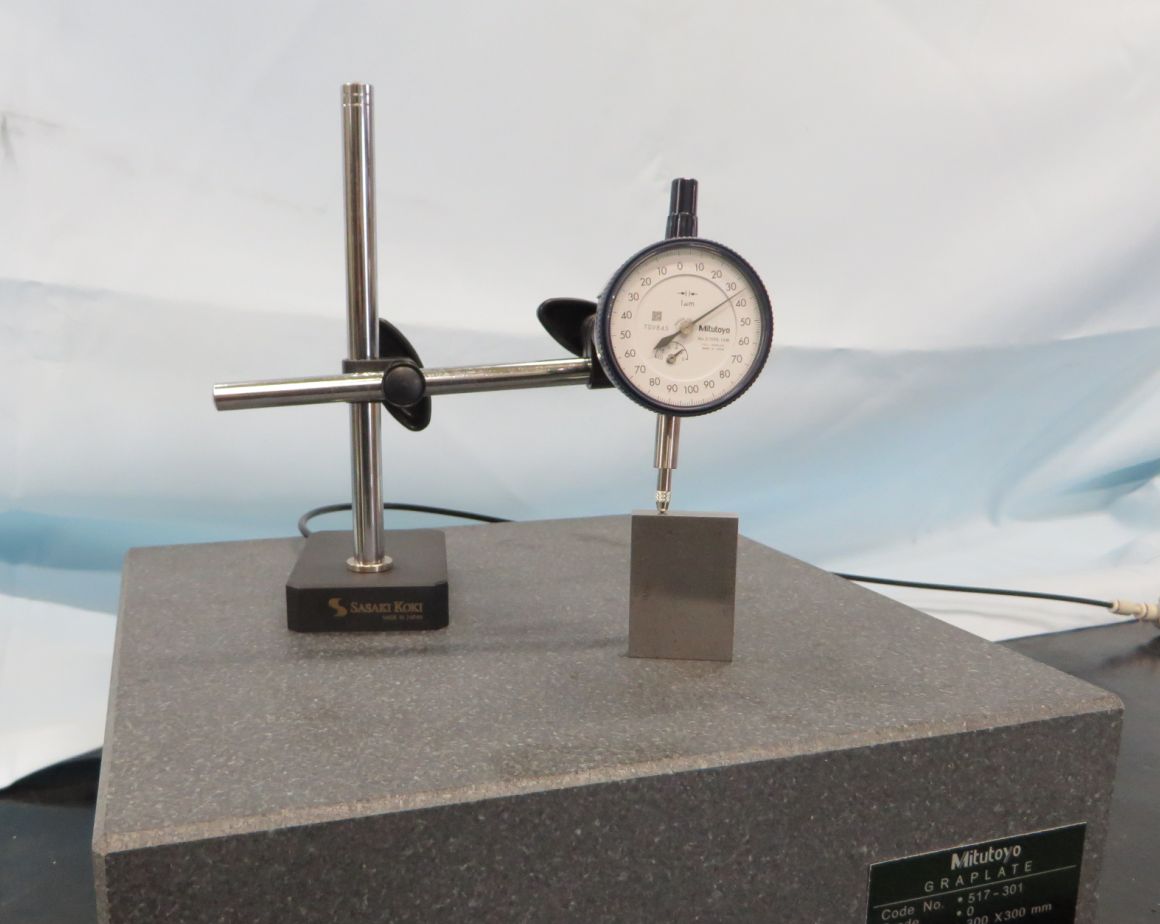

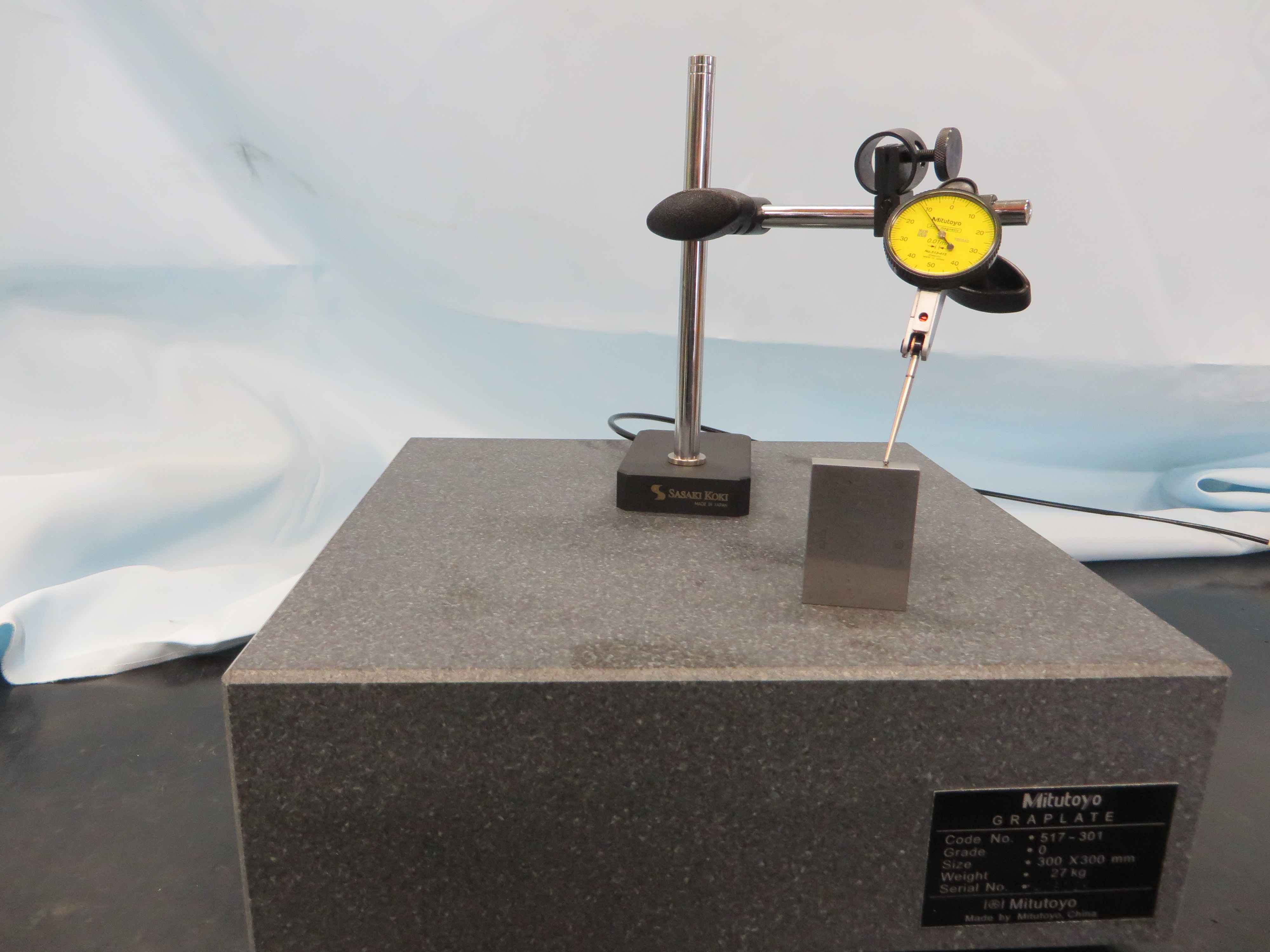

Vacuum suction tool stand is the device which can be used on the

stone surface plate or ceramic surface plate when you need the precision

measurement using dial gauge or pick gauge (pick tester).

Vacuum suction tool stand strongly adsorbs even on the stone surface

plate and ceramic surface plate that can not use the conventional

magnet stand (magnet base).

<Features>

1. Although the magnet stand (magnet base) is limited to use with

an iron platen, it can also be applied to stone and ceramic platens

in the vacuum suction tool stand.

2. The tool stand which is usually used for measurement on stone

platen is large and heavy, so workability of accuracy measurement

is bad, but vacuum suction tool stand is small and lightweight.

So workability is greatly improved.

3. Easy adsorption without vacuum pump: Compressed air from the

factory compressor can be used.

4. Fixing / adsorption is easy to control : Easily adsorption /

opening when holding the ejector.

5. If you already have your magnet stand (magnet base) on the vacuum

suction tool stand, it can be used on stone surface platen, ceramic

surface platen, etc.

6. Since the adsorption power is high, accurate measurement is possible

with a dial gauge or a pick gauge (pick tester).

Vacuum

adsorption tool stand External appearance video (substitution

for magnet stand)

Vacuum

suction tool stand How to use Movie 1 (substitution

for magnet stand)

Vacuum

suction tool stand How to use Movie 2

(Magnet stand (magnet

base) installed version.)

|

Vacuum suction tool stand when dial gauge

is installed

|

Vacuum suction tool stand when pick gauge (pick tester)

is installed

|

|

Vacuum suction tool stand when M8 threaded

support columns is mounted

|

Vacuum suction tool stand when inserting air tube into

ejector

|

<Performance>

Moment load holding force test result

|

P=0.3MPa

|

P=0.4MPa

|

P=0.5MPa

|

P=0.6MPa

|

|

X

|

4.2

|

6.0

|

6.0

|

6.3

|

|

Y1

|

5.2

|

7.8

|

7.8

|

7.8

|

|

Y2

|

5.2

|

6.8

|

7.2

|

7.2

|

|

Z

|

24.8

|

30.5

|

30.6

|

30.6

|

|

|

|

|

|

(Unit: kg)

|

<Basic configuration>

Vacuum suction tool stand VSTS - WZ is equipped with the following

equipment.

・Main body・・・・1 piece

・Ejector・・・・・・1 piece

Optional items

Support columns

Washers (for Support columns)

Air tubes

Valves for opening and closing

Please purchase separately.

An air supply source such as a compressor is required.

Please supply air at a pressure of 0.4 MPa to 0.6 MPa.

<Basic Specs>

・Size: H18 mm × W 60 mm × D 92 mm (including ejector 108 mm)

・Weight: 760 g

・Supply air: clean air of 0.4 MPa to 0.6 MPa

<Other special specifications>

Please contact us if you wish to request other special specifications

<F.A.Q. >

Q1. What is the size of screw holes to stand upright the support

column

on the main body of vacuum suction tool stand?

A1. It is a coarse thread of M8 × P1.25. It is also possible to

set different size of the thread screws by option (paid).

Q2. Why can you make vacuum with compressed air of air compressor?

A2. Small vacuum generator called ejector is attached to the back

of the main body. Air is supplied from the ejector supply port and

air is discharged from the exhaust port to create an air current.

At the bottom of the main body there is a groove of an air reservoir,

the air in it is discharged on the air flow created by the ejector

and a vacuum is created.

Common precautions for vacuum system equipment

Please read before using the vacuum suction tool

stand.

Warning

|

1

|

If the adsorbate (workpiece) falls and is considered

dangerous, please provide safety measures to prevent falling. |

|

2

|

Please do not use it when pressure of 0.1 Mpa

or more is always applied to the vacuum circuit side. Since

the vacuum equipment is not explosion-proof structure, there

is a danger of causing damage to the main body. |

|

3

|

Please pay attention to the drop of vacuum pressure

due to trouble of supply air and power supply. Since there is

a danger that the adsorbate will fall due to a decrease in adsorption

power, please give a safety measure. |

|

4

|

When two or more pads (vacuum suction

tool stands) are piped to one ejector in a vacuum circuit, if

one pad suffers adsorption failure (leakage), there is a danger

that the other pads will be detached due to a decrease in vacuum

pressure. |

|

5

|

Please do not use such as to block the exhaust

port of the ejector or increase the exhaust resistance. Vacuum

does not occur, or vacuum pressure may decrease. |

|

6

|

Do not use it in corrosive gases, flammable gases,

explosive gases, chemicals, sea water, steam atmosphere or where

they adhere. Also, please never inhale them. |

|

7

|

Please attach a protective cover where sunlight

is irradiated. |

|

8

|

Regularly perform maintenance and inspection on

the silencer element of the ejector and the filter element of

the vacuum filter. Clogging of the element may cause performance

degradation or trouble. |

|

9

|

Please understand the vacuum ejector replacement

element well for the element replacement operation. |

|

10

|

Please check each port of the ejector according

to the text of the manual and piping. There is a risk of causing

damage to the main body if you mistake the piping. |

|

11

|

For the ejector supply air, remove drains and

dust and use clean air. Do not refuel with lubricator. Impurities

contained in compressed air and oil may cause malfunctions and

performance degradation. |

|

12

|

Please do not give a strong tensile force or extreme

bending to the lead wire. It may cause breaks. |

|

13

|

If there is a lock nut in the product,

please tighten it securely by hand tightening without using

a tool for tightening. If tightening with a tool, it may cause

damage to the lock nut or the main body. Also, if it can not

be securely tightened, there is a possibility that the lock

nut is loose and the initial setting is out of order |

|

14

|

Do not swing or rotate the product whose resin

body rotates forcibly. It may cause breakage or leakage of the

main body. |

Vacuum suction tool stand (substitute for magnet

stand)

Inquiry

SASAKI

KOKI Co,INC.

TOP

|