|

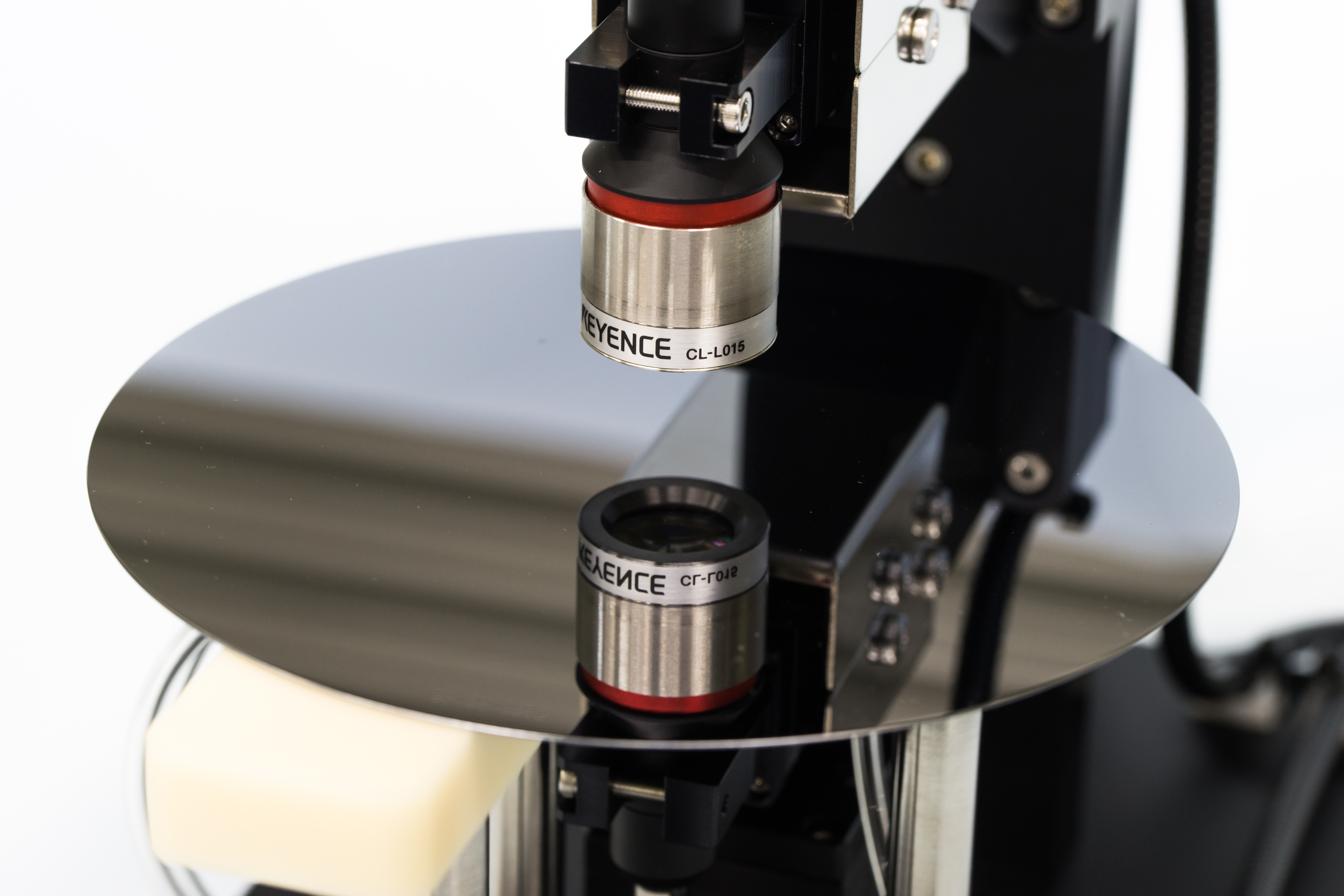

NON-CONTACT

THICKNESS MEASURING DEVICE

OZUMA

CL

(For Wafers Thickness

Measurement )

<USE>

High precision Thickness Measurement for wafers

like Si(silicon) and GaAs(gallium arsenide) for sem-iconductorsand

metals.

<FEATURES>

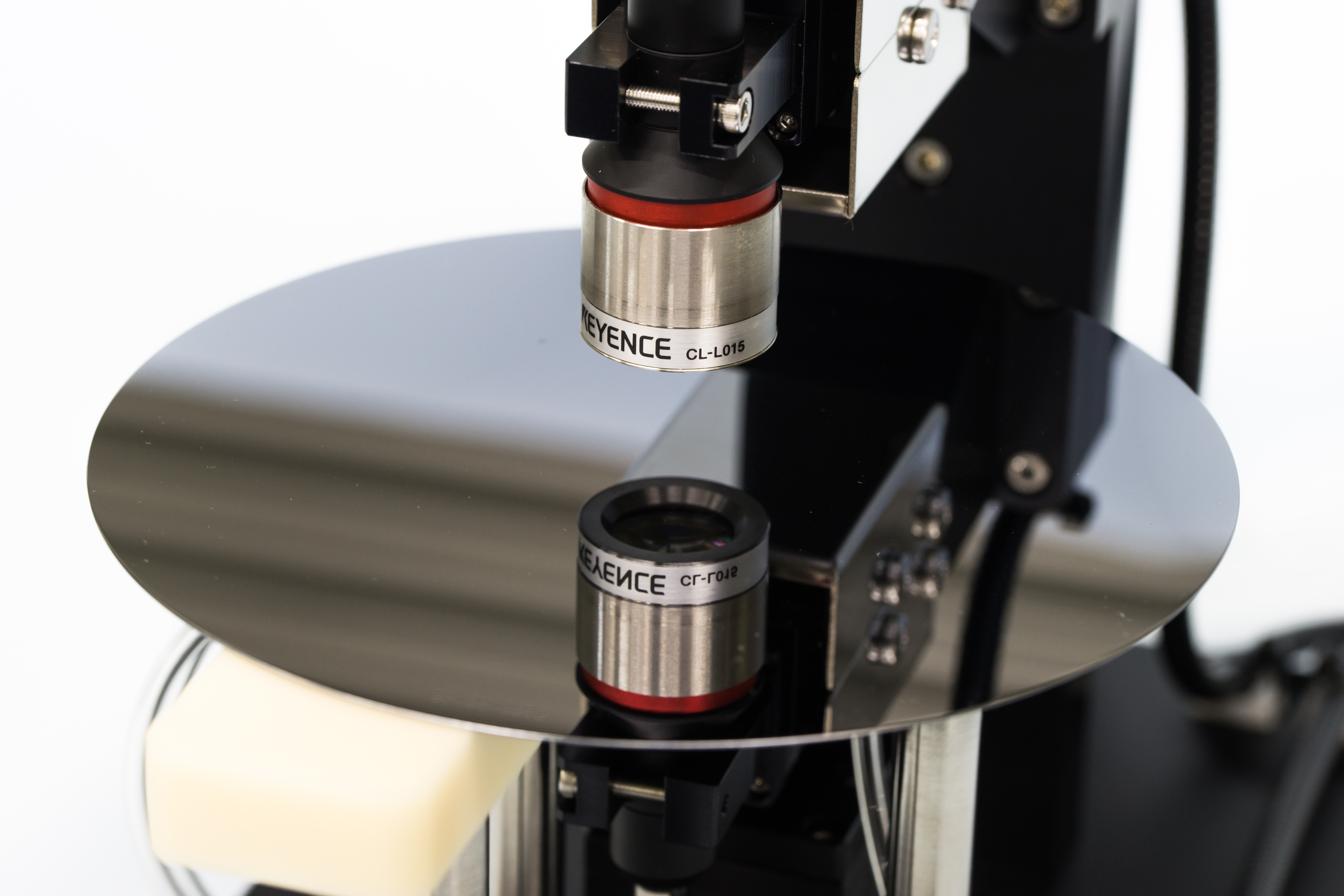

1.Non-contact thickness measurement is possible

with the laser method, and it does not cause damage such as scratches

and contamination.

2.High precision non-contact thickness measurement possible.

3.Repeated thickness, warpage, parallelism, etc. can be measured.

4.Since the measurement is performed with the laser sensor heads

placed opposite each other, the thickness can be measured accurately

without being affected by the lift of the object being measured.

<PERFORMANCE>

Resolution 0.01μm

Range of thickness measurement Max.10mm

Power supply AC100V 50/60Hz 3A

Weight: Approximately10kg

�

<SYSTEM BREAKDOWN>

Standard system consists of the following equipments:

| ① |

Thickness measuring equipment |

1set

|

| ② |

Table (to be selected from several

tables for your needs) |

1set

|

| ③ |

Control box |

1set

|

| ④ |

Switch box |

1set

|

| ⑤ |

Display unit (7" color LCD

touch panel) or laptop PC for measuring control |

1set

|

| ⑥ |

Connecting cables. |

1set

|

| ⑦ |

Fine adjustment gauge

(Select thickness) |

1 peace

|

| ⑧ |

Standard software for measuring

control |

1set

|

and more options are available for your own use.

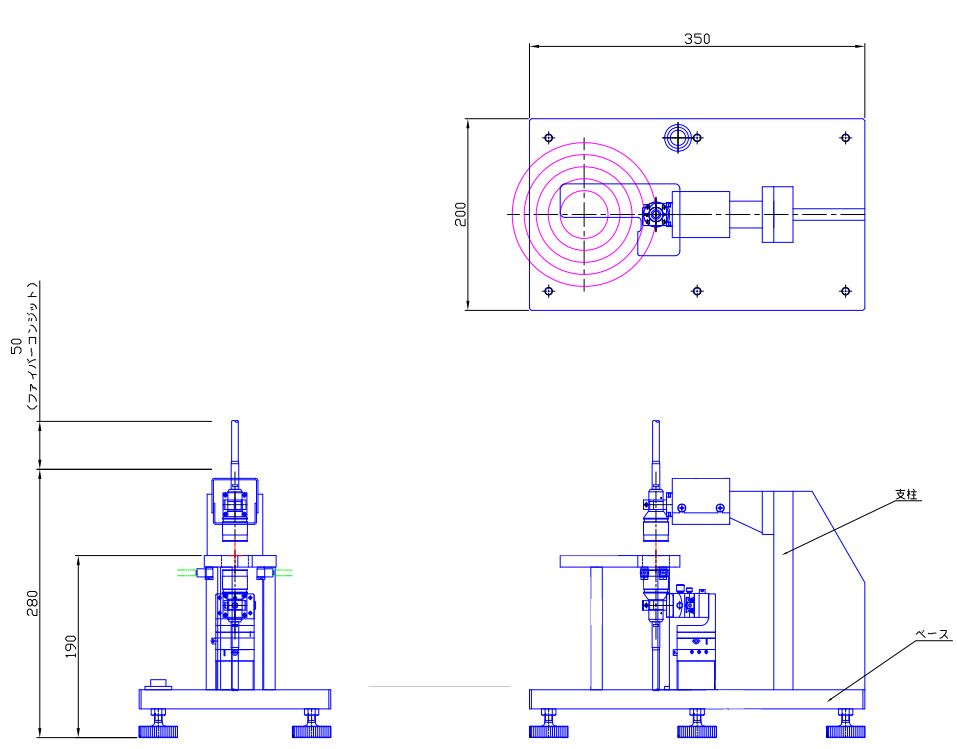

<Dimension Drawings>

(Remarks)

| *1 |

It may not be possible to measure

curvatures depending on the curvature level and stiffness.Please

contact us for further information. |

<Customization Request>

Please contact us if you need other special specifications.

NON-CONTACT THICKNESS

MEASURING DEVICE

<Send

your inquiries to>

Sasaki-koki,

Co, INC.

TOP

|